Custom Air-Cooled Aftercoolers for Your Compressor System

Custom air-cooled aftercoolers are engineered to address specific cooling and moisture removal needs in compressed air systems, offering tailored solutions for industries like aerospace, oil and gas, and specialized manufacturing. These bespoke units ensure peak performance, durability, and efficiency in unique or demanding applications.

- Tailored Design: Custom aftercoolers are built to match exact compressor specifications, flow rates, and environmental conditions for optimal cooling.

- Material Options: Choose from aluminum, stainless steel, or corrosion-resistant alloys to suit harsh or specialized operating environments.

- Power Configurations: Available in AC, DC, or pneumatic-driven models to accommodate mobile, remote, or hazardous location requirements.

- Compact Solutions: Designed for space-constrained setups, with flexible mounting and connection options to fit unique system layouts.

- Enhanced Features: Options like high-capacity fans, low-pressure drop designs, and integrated moisture separators for critical applications.

- Industry Compliance: Custom units meet ASME, ISO, or application-specific standards, ensuring safety and reliability in regulated industries.

Custom Air-Cooled:

Industrial Applications

- High-Flow Configurations

- Specialized Materials

- Flow Rates: 50-10,000 SCFM

Custom Core-Only:

Industrial Applications

- Integration with Existing Systems

- Compact Heat Exchanger Cores

- Custom Fittings & Mounts

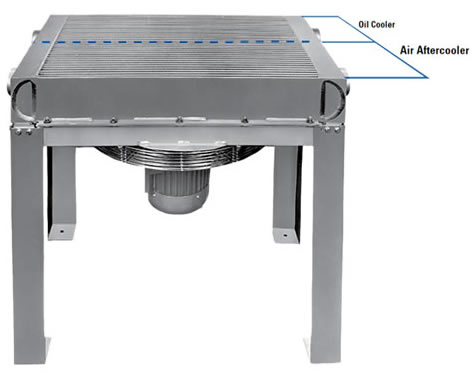

Custom Air-Cooled Aftercoolers

Custom air-cooled aftercoolers provide tailored solutions for compressed air systems in industries requiring precise cooling and moisture control, such as chemical processing, marine applications, and heavy machinery. These units are designed to meet unique specifications, ensuring efficient heat dissipation and system reliability in challenging or specialized environments.

Why Choose Custom Aftercoolers

Standard aftercoolers may not meet the demands of unique compressor setups or extreme conditions. Custom units are engineered to match exact flow rates (50-10,000 SCFM), pressure ratings (up to 300 PSI), and temperature limits (up to 400°F). Options include specialized materials like stainless steel for corrosive environments, compact designs for tight spaces, and power configurations (AC, DC, or pneumatic) for diverse applications. Features like high-efficiency fins, vibration-resistant mounts, and integrated separators enhance performance for critical processes.

Customization Options

Custom aftercoolers offer flexibility in design, including core-only units for integration with existing airflow systems, high-capacity fans for hot climates, and low-pressure drop configurations for energy efficiency. Connection types (NPT, flange, or SAE) and mounting options are tailored to your system. Compliance with ASME or industry-specific standards ensures safety and reliability, while optional accessories like pressure gauges or automatic drains add functionality for specialized needs.