Mobile DC Aftercoolers

Distribution, Maintenance, & Custom Solutions

Materials and Connections:

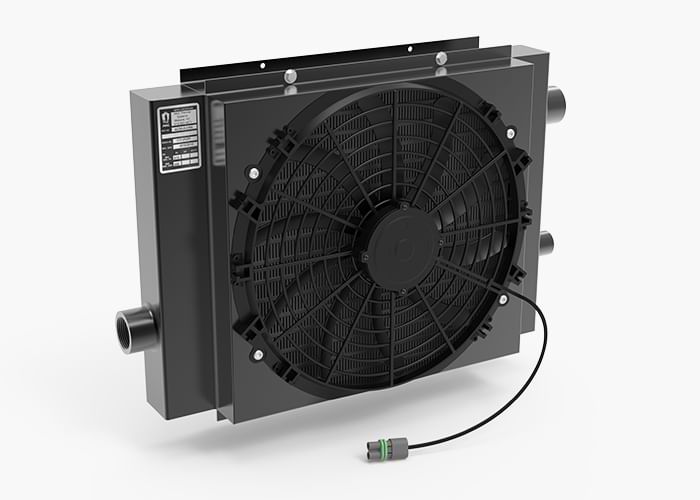

Our mobile DC aftercoolers are constructed from high-grade aluminum, ensuring a lightweight yet durable design with excellent thermal conductivity. Standard connections utilize SAE fittings, with options for NPT or flange connections to suit diverse system requirements.

Motor Options:

Available configurations include core-only units without a fan for integration with existing airflow systems, units with DC-powered fans for battery-operated setups, or models with hydraulic motors for heavy-duty applications, offering versatile cooling solutions.

Configuration:

These aftercoolers support flexible installation in either vertical or horizontal orientations, provided proper measures are taken to purge air from the system during startup to ensure optimal performance and efficiency.

Mobile DC Aftercoolers

Our mobile DC aftercoolers are engineered for portability, durability, and efficiency, making them ideal for compressed air systems in mobile and field applications such as construction equipment, agricultural machinery, and off-road vehicles. Built to withstand challenging conditions like dust, vibrations, and extreme temperatures, these aftercoolers are typically powered by DC electrical systems or hydraulic motors, ensuring reliable cooling in remote environments. Their compact design and robust performance make them essential for maintaining air quality and equipment longevity in demanding operations.

Below are key applications where mobile DC aftercoolers play a critical role in ensuring optimal performance and system reliability:

Construction Machinery

Equipment like excavators, loaders, and compactors generates significant heat during operation. Mobile DC aftercoolers cool compressed air, condensing moisture to protect pneumatic tools and hydraulic systems from corrosion and overheating. This ensures consistent performance and reduces maintenance costs in rugged construction sites where reliability is paramount.

Agricultural Equipment

Tractors, sprayers, and harvesters rely on compressed air systems for various functions. DC aftercoolers manage heat and moisture in these systems, preventing damage to components and maintaining operational efficiency during long hours in dusty or humid conditions. This enhances equipment durability and supports uninterrupted fieldwork.

Mining Operations

In mining, vehicles such as drills and haul trucks operate in harsh, dusty environments. Mobile DC aftercoolers cool compressed air to remove moisture, protecting air-driven tools and systems from wear. This boosts equipment uptime and reliability, critical for maintaining productivity in remote mining locations.

Industrial Mobile Systems

Mobile industrial setups, including portable compressors and generators, require efficient cooling to ensure clean, dry air. DC aftercoolers reduce air temperature and moisture content, safeguarding sensitive components and improving system performance in temporary or mobile manufacturing operations.

Forestry Machinery

Forestry equipment like feller bunchers and log loaders operates in debris-heavy, remote environments. Mobile DC aftercoolers prevent overheating and moisture buildup in compressed air systems, ensuring consistent operation and extending the lifespan of these machines in challenging conditions.

Utility Vehicles

Utility vehicles used in maintenance or emergency services rely on compressed air for tools and systems. DC aftercoolers deliver dry, cool air to prevent corrosion and ensure reliable performance, supporting critical tasks in diverse environments, from urban settings to remote locations.