Moisture Separators for Compressed Air Systems

Distribution, Maintenance, & Replacement Parts

Key Features: Universal Compatibility - 99.5% Water Removal Efficiency - Minimal Pressure Loss - Cost-Effective Design

Technical Specifications: Maximum Pressure: 300 PSI - Maximum Operating Temperature: 180°F - Minimum Recommended Temperature: 32°F - Flow Rates: 50 to 5,000 SCFM

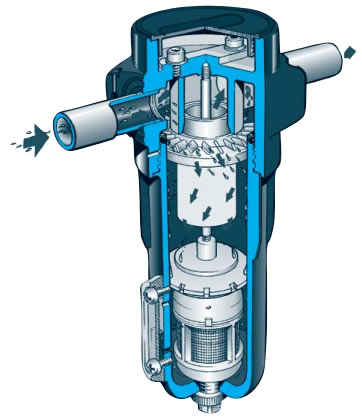

Moisture separators are vital for optimizing compressed air systems when paired with air-cooled aftercoolers. As the aftercooler reduces the temperature of compressed air, water vapor condenses into liquid droplets. These separators employ advanced centrifugal or coalescing mechanisms to efficiently extract liquid water and oil from the air stream, preventing it from reaching downstream equipment. This safeguards against corrosion, contamination, and performance degradation in pneumatic tools, manufacturing processes, and sensitive applications like food processing or spray painting.

Constructed from corrosion-resistant materials such as stainless steel or aluminum, our moisture separators are designed for durability and low maintenance. They feature high-efficiency filtration media and robust drain systems, available in automatic or manual configurations, to ensure consistent water removal. By delivering clean, dry air, these units enhance system reliability, reduce maintenance costs, and extend the lifespan of compressors and downstream components. Their compact design allows for easy integration into both stationary and mobile compressed air systems, making them suitable for industries ranging from automotive to construction.

Additional features include customizable connection options (NPT, flange, or SAE), low-pressure drop for energy efficiency, and compliance with ASME standards. Optional upgrades like sight glasses, differential pressure gauges, and high-capacity drains provide enhanced monitoring and performance for critical applications. Whether for industrial plants or portable compressors, our moisture separators ensure optimal air quality and system performance.

Models with Automatic Drain

Automatic drain models feature electronically or pneumatically controlled valves that expel collected water and contaminants without manual intervention. These are ideal for high-flow systems or applications requiring minimal downtime, such as continuous manufacturing or remote operations. Options include timed drains or zero-loss designs for maximum efficiency.

Models with Manual Drain

Manual drain models are equipped with a robust valve for user-controlled water removal, suited for smaller systems or applications with intermittent use. These cost-effective units are easy to maintain and reliable for workshops, construction sites, or low-maintenance setups where regular checks are feasible.