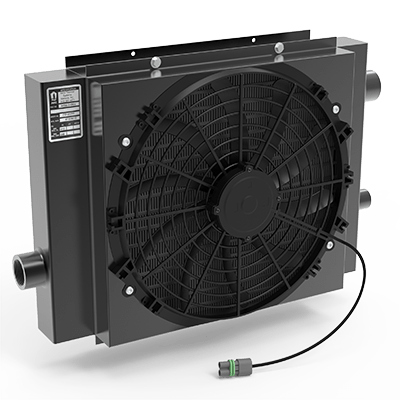

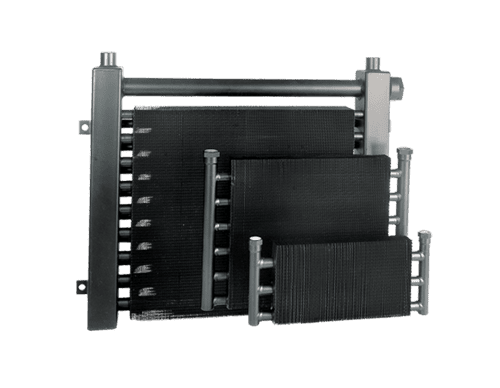

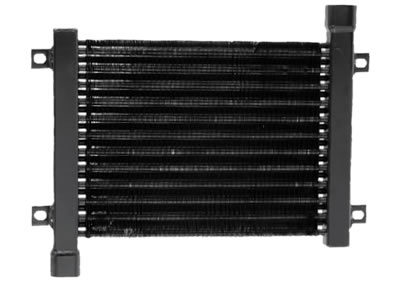

Compressor Cooling Solutions

Benefits and Reasons for Air-Cooled Aftercoolers

Air-cooled aftercoolers are critical for maintaining the efficiency and longevity of compressed air systems. By cooling hot compressed air and removing moisture, these systems protect downstream equipment, enhance air quality, and reduce operational costs. Our solutions are designed to deliver reliable performance, tailored to your specific cooling needs, ensuring optimal system operation across various industries.

- Moisture Reduction: Cools air to condense up to 75% of water vapor, preventing corrosion and damage in pneumatic tools and processes.

- Energy Efficiency: Lowers air temperature, reducing the load on downstream dryers and minimizing energy consumption.

- Equipment Protection: Reduces heat stress on compressors and downstream components, extending service life and minimizing maintenance.

- Versatile Installation: Compact designs allow for flexible mounting options, ideal for space-constrained or remote setups.

- Improved Air Quality: Removes contaminants and moisture, ensuring clean, dry air for sensitive applications like painting or food processing.

- Cost-Effective Operation: Low maintenance and no water supply needs make air-cooled aftercoolers a budget-friendly cooling solution.